Drying and heat treatment

inTEC designs pre-heating ovens and drying systems according to your specific requirements. We offer drying systems that use different technologies such as air circulation, UV and infra-red light, as well as telescopic and transverse drying systems.

︽ Drying system – air circulation

Drying system – air circulation

We supply a range of drying systems. Generally, dryers are part of a continued automation system combined with a coating system and are built into existing transport structures or production lines.

The design is developed according to the specifications, the shape of the parts, the ambient conditions and the project requirements.

Equipment variants:

» Heated by gas, oil, hot or warm water

» Single or multi-chamber system

» Heat recovery

» Temperature regulator

» Filter systems

» Condensation drying

» Targeted air routing and extraction

» Built-in transport systems (rollers, chain conveyors, etc.)

» Roller doors

»

Control systems for optimum efficiency

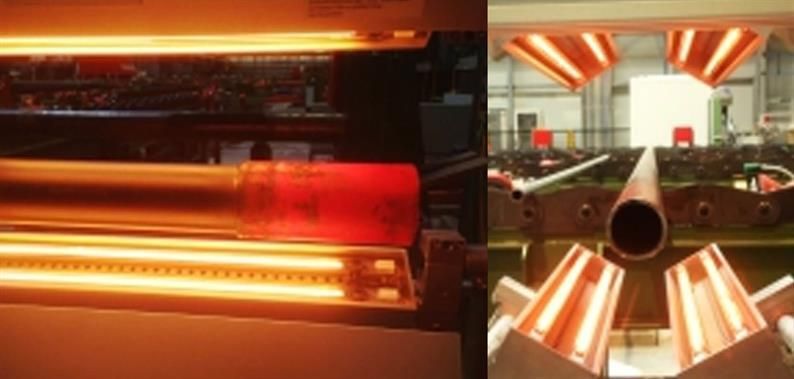

︽ UV drying system

UV drying system

Different kinds of UV drying systems are provided to cure UV paint or ink for pipes, steel parts and plates.

Generally, dryers are part of a continued automation system combined with a coating or marking system and are built into existing transport structures or production lines.

The design is developed according to the specifications, the shape of the parts, the ambient conditions and the project requirements.

Videos:

UV-Tube coating

︽ Infra-red drying system

Infra-red drying system

Generally, infra-red drying systems are combined with a coating system and built into existing transport structures or production lines.

The design is developed according to the specifications, the shape of the parts, the ambient conditions and the project requirements.

Industry press:

︽ Telescopic drying booth

Telescopic drying booth

The telescopic drying booth can be pushed together when not in use to save space. To dry, the telescopic drying booth is extended over the treated material.

The design is developed according to the specifications, the shape of the parts, the ambient conditions and the project requirements.

Equipment variants:

» Heated by gas, oil, hot or warm water

» Heat recovery

» Temperature regulator

» Filter systems

» Air circulation/exhaust air/dryer mode

» Targeted air routing and extraction

»

Control systems for optimum efficiency

Videos:

Coating surfaces with ventilation

︽ Moveable drying system

The moveable drying system can be moved to any location. To dry, the moveable drying booth is extended over the treated material.

The design is developed according to the specifications, the shape of the parts, the ambient conditions and the project requirements.

Equipment variants:

» Moveable on rails or rollers

» Heated by gas, oil, hot or warm water

» Heat recovery

» Temperature regulator

» Filter systems

» Air circulation/exhaust air/dryer mode

» Targeted air routing and extraction

» Control systems for optimum efficiency

Industry press:

Videos:

Coating surfaces with ventilation

︽ Pre-heating oven

Pre-heating oven

Generally, pre-heating ovens are combined with a blasting or coating system and built into existing transport structures or production lines.

The design is developed according to the specifications, the shape of the parts, the ambient conditions and the project requirements.

Equipment variants:

» Heated by gas, oil, hot or warm water

» Heat recovery

» Temperature regulator

» Air circulation/heat mode

» Filter systems

» Air circulation/exhaust air/dryer mode

» Targeted air routing and extraction

» Built-in transport systems (rollers, chain conveyors, etc.)

» Roller doors

» Control systems for optimum efficiency